A simple anatomy of the Rolex Sea-Dweller (Ref. 16600) - Part 3

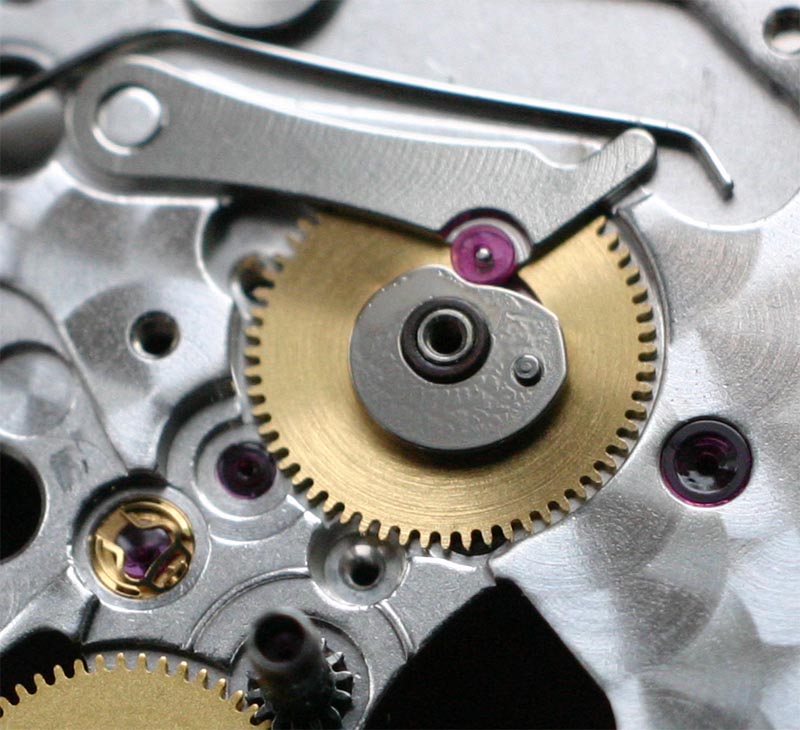

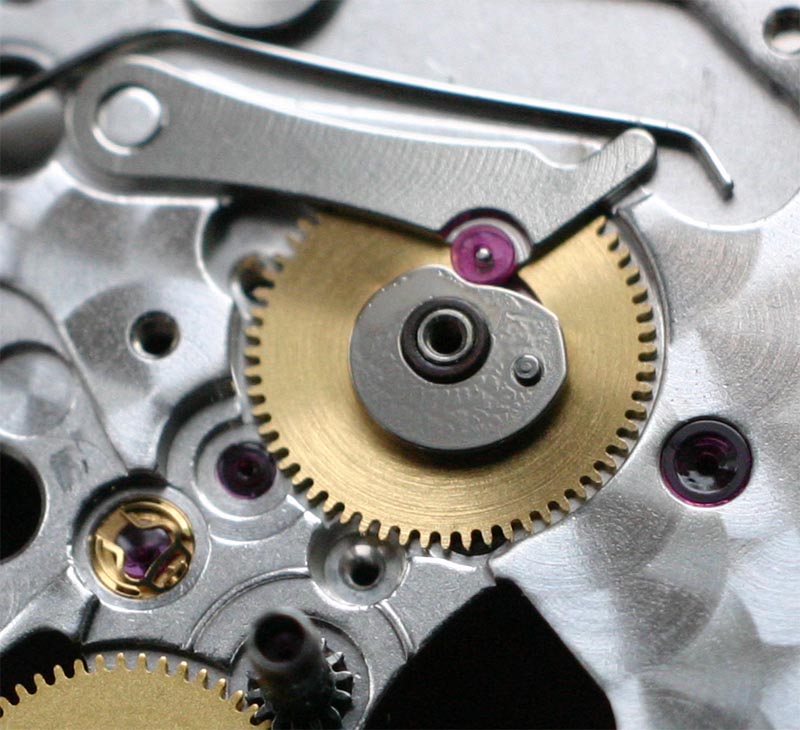

Let us consider the Rolex Cal. 3135 Automatic Winding Module. The automatic winding system is bi-directional, in the style of ETA/Eterna. The two red coloured wheels seem to be made of a light alloy, and both are coated with Teflon, for lubrication purposes of the Outer Gear Teeth and Inner Clicks. The red wheels are trademarks of Rolex. Unlike ETA's reversing wheels, Rolex designed the wheels to be dismountable (for better servicing). They are easier to clean and oil (only pivots should be oiled). Thus, they are more durable than ETAs. The picture below shows a disassembled first wheel. There are four clicks on two swinging levers.

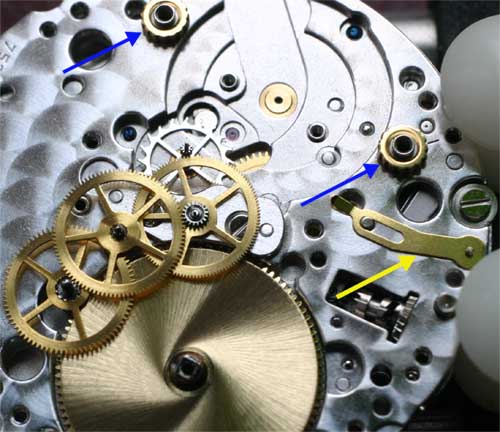

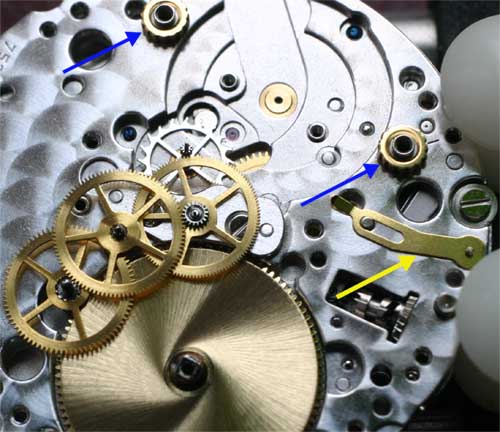

The picture below shows all Bridges removed. The wheel train system is traditional for a movement with central seconds. Because it uses fewer wheels, this system is very robust and very reliable. However, the construction requirements are tougher. In other systems where central seconds are made as a pinion added to the train wheel, the automatic winding module can be placed to one side, making the movement thinner. Rolex's construction is such that the automatic winding device is placed above the wheel train. This makes the movement being 6 mm high (quite thick for a modern movement). From the picture, one can notice a gold lever (yellow arrow). It is a stop device and it keeps the balance rim from moving when the crown is pulled out. Two regulating nuts for balance bridge (blue arrows) are made for balance endshake adjustment. 1/8 of a turn makes about 0.01 mm.

Normally for high quality watches, the Calendar Bridge (hidden under the dial) is finished in Perlage style. To reduce friction, the calendar ring is mounted on 3 jewels.

In the picture below, one can see the instantaneous date changing mechanism. There is a steel part of complex shape (2) mounted on the date wheel (1). It can move at a certain small angle, set by the slot. The jewel roller (5) moves on the surface of the steel part (2). The lever (3) with roller is pressed against the steel part (2) with a strong spring (4). At approximately 12 p.m. the jewel roller reaches the indentation or dip in the steel part (2). Under the pressure of the spring, the roller moves to the center of the date wheel (1) and moves the steel part at an angle sufficient to catch the tooth of the date wheel and move it on one step. In the Fig. 13 the date wheel (1) is in the position immediately after date changing.

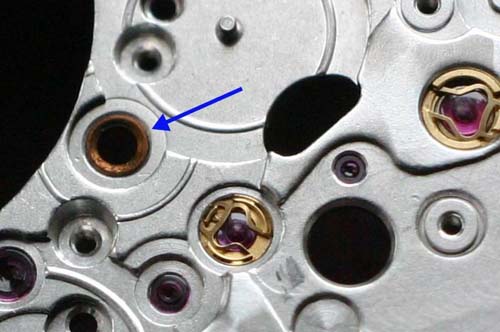

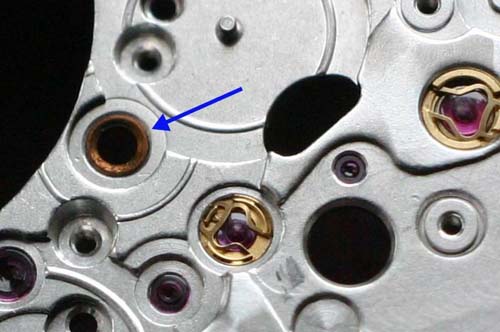

The picture below shows a bronze bushing instead of a central jewel. This construction is more reliable than a jewel during shocks. Furthermore, it is easier to replace the bushing than a Jewel, so it is not a disadvantage, but rather a feature of this Calibre.

For more reading, please visit the following great sites… pictures and text are taken from:

http://people.timezone.com/mdisher/a...135/3135_1.htm

http://marina.fortunecity.com/westindia/59/dfg.htm

Let us consider the Rolex Cal. 3135 Automatic Winding Module. The automatic winding system is bi-directional, in the style of ETA/Eterna. The two red coloured wheels seem to be made of a light alloy, and both are coated with Teflon, for lubrication purposes of the Outer Gear Teeth and Inner Clicks. The red wheels are trademarks of Rolex. Unlike ETA's reversing wheels, Rolex designed the wheels to be dismountable (for better servicing). They are easier to clean and oil (only pivots should be oiled). Thus, they are more durable than ETAs. The picture below shows a disassembled first wheel. There are four clicks on two swinging levers.

The picture below shows all Bridges removed. The wheel train system is traditional for a movement with central seconds. Because it uses fewer wheels, this system is very robust and very reliable. However, the construction requirements are tougher. In other systems where central seconds are made as a pinion added to the train wheel, the automatic winding module can be placed to one side, making the movement thinner. Rolex's construction is such that the automatic winding device is placed above the wheel train. This makes the movement being 6 mm high (quite thick for a modern movement). From the picture, one can notice a gold lever (yellow arrow). It is a stop device and it keeps the balance rim from moving when the crown is pulled out. Two regulating nuts for balance bridge (blue arrows) are made for balance endshake adjustment. 1/8 of a turn makes about 0.01 mm.

Normally for high quality watches, the Calendar Bridge (hidden under the dial) is finished in Perlage style. To reduce friction, the calendar ring is mounted on 3 jewels.

In the picture below, one can see the instantaneous date changing mechanism. There is a steel part of complex shape (2) mounted on the date wheel (1). It can move at a certain small angle, set by the slot. The jewel roller (5) moves on the surface of the steel part (2). The lever (3) with roller is pressed against the steel part (2) with a strong spring (4). At approximately 12 p.m. the jewel roller reaches the indentation or dip in the steel part (2). Under the pressure of the spring, the roller moves to the center of the date wheel (1) and moves the steel part at an angle sufficient to catch the tooth of the date wheel and move it on one step. In the Fig. 13 the date wheel (1) is in the position immediately after date changing.

The picture below shows a bronze bushing instead of a central jewel. This construction is more reliable than a jewel during shocks. Furthermore, it is easier to replace the bushing than a Jewel, so it is not a disadvantage, but rather a feature of this Calibre.

For more reading, please visit the following great sites… pictures and text are taken from:

http://people.timezone.com/mdisher/a...135/3135_1.htm

http://marina.fortunecity.com/westindia/59/dfg.htm

sub is way more than enuf for me le. I nvr even get to dive into 2 meters deep water. Btw,last time i heard some article said about how deep human can dive underwater...if memory bo salah its 30 meters.Any diver in the house to verify this...?

sub is way more than enuf for me le. I nvr even get to dive into 2 meters deep water. Btw,last time i heard some article said about how deep human can dive underwater...if memory bo salah its 30 meters.Any diver in the house to verify this...?

than shld i be offered the title of Uncle liao lor?!

than shld i be offered the title of Uncle liao lor?!

Comment